China plastic mold bottle cap mould china new design cap mould for 28mm cap

Product Description

Contacts:Miya wang

Tel:0576-85183228

Mobile:+86 15990049143

what's app:+86-15990049143

we chat/qq:736201288

plastic mold bottle cap mould

1.We can design the mould according to your sample or 2D/3D drawing.

2.Mould steel: P20, #2316 steel, S136 and so on, or according to customer's request.

3.Delivery time: 30-60days.

4.Certifiable life: ≥1,000,000 shots

5.4cavity, 6cavity, 8cavity, 12cavity, 16cavity, 20cavity, 24cavity, 32cavity, 48cavity etc.

6.Germanic " Hotset" Brand heat fittings and quality thermocouple.

7.Insert materials: cavity and core with imported 2316 stainless steel or S136, P20, and so on, or according to customer's request.

Tips Detail explain,

1)2316 steel from German

1, Hardness: HRC45-48

2, HBS<=235

3.Surface:black or polish

4.Technique:hot rolled or Forged

2316 plastic mould steel characters:

1 medical carbon high chrome martensite shape stainless steel

2 high purity good performance of high mirror polish,anti-acid, anti-rust after heat treatment

3 good corrosion resistance

4 resistance for erosive attack,good stability

2) S136 steel from Sweden win hundred, Japanese Datong

1. Hardness: HRC45-48

2. Annealing: 215HB

S136 plastic mould steel characters:

1. Belong to medial carbon high chrome Martensite shape stainless steel

2. High purity , good performance of high mirror polishing, anti-acid, anti-rust after heat- treatment

3. Good corrosion resistance

4. Resistance for erosive attack

5. Low deformation rate

6. Good stability

Hot runner

Chinese or internatinal famous brand hot runner systems.Hot runner or cold runner with good cooling system.hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for plastic production, cavity with lower injection pressure to reduce wear and tear of mould parts

Heating system

with double heating system, it has separate temperature control mode ,the heat bar are used to heat hot-runner mainfold , small heaters supply the heating temperature for cavity nozzle continuously.

Cooling system

each parts including core ,cavity has independently cooling system.

Heating treatment

mechanical treatment cavity and core to prolong service life ,nitrogen treatment with neck screw. with fitly operation ,guarantee Long using life over 2.0 million times of injection cycle.

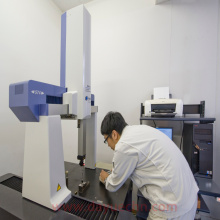

Advanced Testing and Processing Equipment

Many machine tools are imported from America and Japan, such as Machine center, CNC lathers, EDM and so on. All of these increases processing precision, good interchangeability

Note tips:

1. when you stop producing or remove the mould, please paint antirust paint on cavity, thread mouth, core to prevent mould sweat and corrosion.

2. If the mould is unuse,you can put it to dry place and paint anticorrosive oil on outer to Prevent moisture.for next time use.

Special satisfied service

1.we will send the weekly mould process report and tooling schedule each 5-10 work days.

2. we will send the first testing sample for buyer's inspection and work out improvement requirements.

3. we will send the mould testing video before shipment

2013 OEM china plastic mold bottle cap mould china new design cap mould for 28mm cap

Business Step map

1.R&D | We support customer R&D. Make the files or improve the design if you needed. |

| |

2.Quotation Making | Mould Quotation will be finished in 1 day according to information we get. |

| |

3.Negotiation | The quality, price, material, delivery time, payment item, etc. |

| |

4.Mould Design | 3-5 days for mould and product 3D/2D drawing design. |

| |

5.Mould | According to customer'request to build the mould. Before make the mould, we send mould design to be approved by customer first. Mould will be usually finished in 30-60days. |

| |

6.Mould Testing | When moulds are finished, we will test the mould to check it satisfied consumer's needs. And we will send samples for consumer reference. |

| |

7. Sample confirmation | If customer is not satisfied with the first samples when it is come out. We modify the mould and untill meet customer's satisfaction. |

| |

8.Delivery | Delivery goods by sea or by air, according to customer's requirement. |

9.company history | More than 20 years |

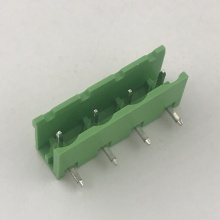

Pet preform Cap for Bottle

Material: with 100% new material(PE&PP)

Inside liner material :TPR

Type: twist off cap ,with tamper evident ring or by you need

Carton dimension: 620*375*465MM or customized

Mini order :100,000 pieces

Fob price: send email to us to get newest price.

Supply ability: 5,000,000 Piece/Pieces / Month

Cap usage :Push/pull cap,Flip-off cap,Flip-top cap,Edible oil cap,Castor cap,Shampoo cap,Mineral water cap,Beverage cap,Detergent cap and so on.

Feature detail : pilfer proof

1) Diameter: 28mm PCO neck

2) Weight: 3.0g.

3) With anti-theft ring/ tamper evident ring.

4) Color: any color by customer

5) Inside liner material: TPR.

6) Package: 5000caps in one carton.

7) screw cap

8) ISO9000 certification and QS certification

Product and company picture view:

Brief Introduction

Thanks to a dozen years of efforts,Taizhou HONGJINGSHENG Pliastic Mould Co.,Ltd.has found its way to success by relying on scientific progress,demanding the best quality and adhering to the business philosophy of surviving the competition by quality and treating the customers with honest and credit.

Our business consists of three categories:machinery series and injection moulds.

INJECTION MOULD:We produce various plastics,PET preform moulds and daily commodity moulds.We have just successfully developed some steel moulds for use in SMC,BMC,and stretching producedure.By virtue of our well-qualified professionals,skilled operators,and imported high-precision machanical qpuipment,the high-precision and high of mould is guaranteed.We will try our best to be the leader in the line of manufacturing injection moulds.

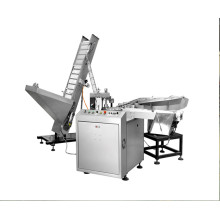

MACHINERY SERIES:We can produce a complete set of equipment intergrating injection-folding-slitting-lining-printing,backed with technology,high-efficiency.And strong after-sales service,making it your ideal choice for the production of bottle lids.

Plastic Product:The company specializes in producing all kinds of plastic caps.Also own more than years experience and the effort of the mould and equipment;we are leader in the line of the caps.

Our plastic moulds and equipments sell well in various cities both at home and abroad.The quality of our products has won favorably comments from customers of all circles.Your visit,telephone and mail are welcome cordially at any time.

Product Categories : Plastic Injection Mold

Premium Related Products